Flexible laminated packaging involves combining two or more layers of different flexible materials (like plastic films, paper, or aluminum foil) with a bonding agent to create a single, multi-layered structure. This lamination process enhances the overall properties of the packaging, providing superior barrier protection, strength, and aesthetic appeal.

Here's an elaboration on its applications across various industries:

1. Food & Beverage Industry: This is by far the largest application area for flexible laminated packaging due to its ability to preserve freshness, extend shelf life, and provide convenience.

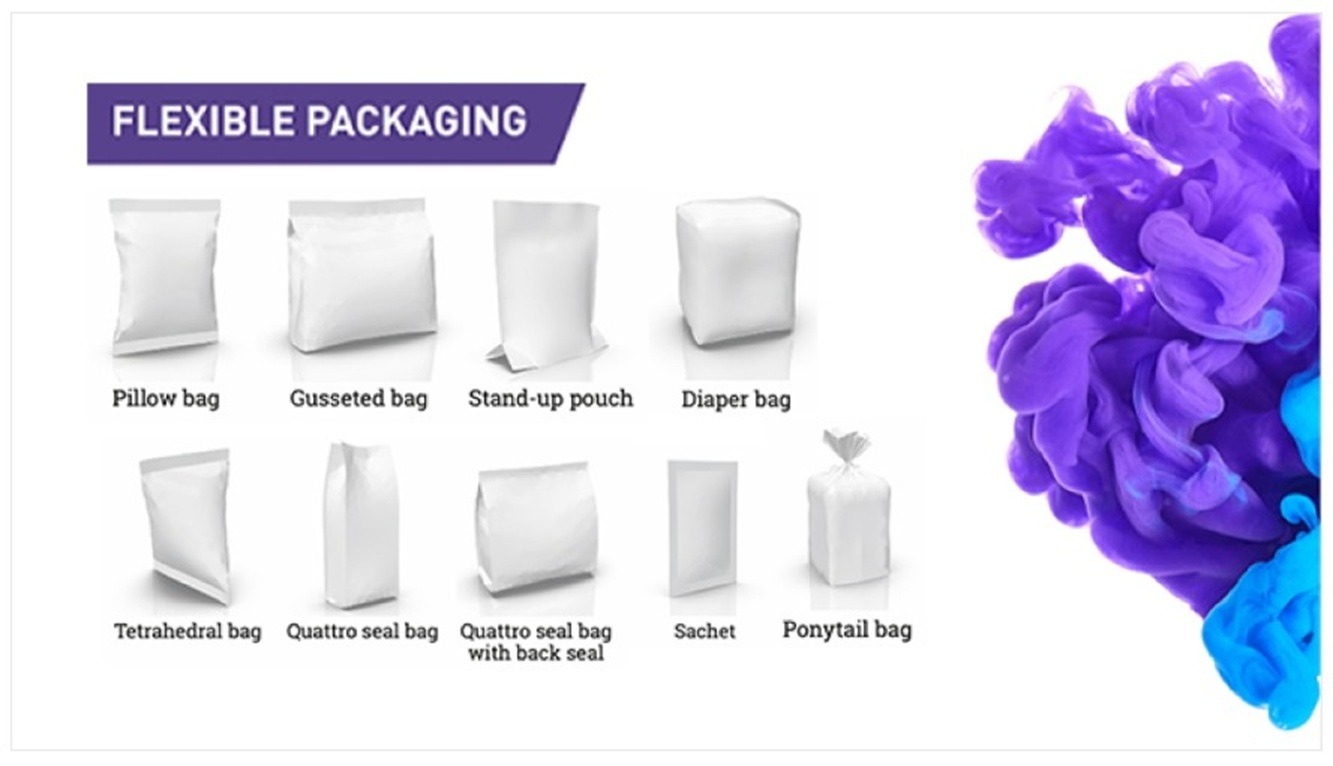

Snacks and Confectionery: Chips, cookies, biscuits, candies, and other snack items often use laminated pouches (pillow bags, stand-up pouches) to protect against moisture, oxygen, and light, preventing staleness and maintaining crispness.

Processed and Ready-to-Eat Foods: Retort pouches for ready meals, soups, sauces, and instant noodles leverage the high barrier properties of laminates (often including aluminum foil) to withstand high-temperature processing and extend shelf life without refrigeration.

Beverages: Pouches for fruit juices, energy drinks, and even wine often utilize laminated structures to prevent oxygen ingress and maintain flavor.

Coffee and Tea: Laminated bags with strong barrier properties (often incorporating aluminum foil) are crucial for preserving the aroma and freshness of coffee beans and ground coffee, as well as tea leaves.

Dairy Products: Pouches for milk powder, cheese, and yogurt often employ laminates for barrier protection and ease of dispensing.

Frozen Foods: Laminated films provide resistance to low temperatures, preventing freezer burn and maintaining the quality of frozen vegetables, meats, and prepared meals.

Dry Goods: Packaging for cereals, pasta, rice, flour, sugar, and pulses benefits from laminates that protect against moisture and pests.

Pet Food: Both dry kibble and wet pet food are commonly packaged in laminated bags and pouches to ensure freshness and prevent spoilage.

2. Personal Care & Cosmetics:

Shampoo, Conditioner, Lotions: Sachets, stand-up pouches, and squeeze tubes for personal care products utilize laminates for portion control, ease of dispensing, and protection against product degradation.

Soaps and Wipes: Wrappers for premium soaps and refill packs for wet wipes benefit from the barrier and aesthetic properties of laminated films.

Cosmetic Samples: Small, single-use sachets for cosmetic creams, foundations, and perfumes are often made from laminates.

3. Pharmaceutical & Healthcare:

Tablets and Capsules: Blister packs and sachets for individual doses of medication often use laminated films to provide a barrier against moisture and oxygen, ensuring product stability and integrity.

Medical Devices: Flexible laminated packaging can be used for sterile packaging of medical instruments and supplies, offering barrier protection and allowing for sterilization processes.

Oral Dehydration Powder: Sachets for rehydration solutions rely on laminates for moisture protection.

4. Agrochemicals:

Fertilizers and Pesticides: Pouches and bags for agrochemical products require robust laminated structures to contain harsh chemicals, prevent leakage, and protect against environmental factors.

The continuous innovation in materials and lamination techniques ensures that flexible laminated packaging remains a highly adaptable and essential solution across a vast range of industries.

Keywords

employ laminates

ensure freshness

barrier protection

flexible materials

moisture oxygen

vast range

essential solution

highly adaptable

continuous innovation

environmental factors

pesticides pouches

medical instruments

sterile packaging

individual doses

squeeze tubes

commonly packaged

dry kibble

pulses benefits

snack items

bonding agent

ground coffee

coffee beans

refill packs

premium soaps

wipes wrappers

laminated bags

aluminum foil

aesthetic properties

laminated films

strong barrier properties

high barrier properties

tea laminated bags

incorporating aluminum foil

portion control ease

refrigeration beverages pouches

maintaining crispness processed

provide convenience snacks

maintain flavor coffee

capsules blister packs

wet wipes benefit

product degradation soaps

prevent oxygen ingress

utilize laminated structures

aesthetic appeal heres

plastic films paper

lamination techniques ensures

rehydration solutions rely

cosmetic creams foundations

wet pet food

pests pet food

frozen vegetables meats

milk powder cheese

extend shelf life

withstand hightemperature processing

instant noodles leverage

light preventing staleness

largest application area

lamination process enhances

single multilayered structure